by: R Gregory Neid, 2025

Canada's First Military Aeroplanes 1917

collection.ngenium.ca Archives CAL-P-OFY-047b

First World War

The First World War, the Great War, the "War to End All Wars" began with Britain declaring war on August 4, 1914. Canada was a young country and under the British North America Act of 1867 did not have control over its foreign policy; Canada was automatically at war. Full independence would not come until the Statute of Westminster in 1931. The First world War ended with the armistice on November 11, 1918.

Canada was an excellent source of war supplies and in 1916 the Imperial Munitions Board was established in Canada to procure war material for the British Ministry of Munitions.

In 1915 Britain was running out of artillery shells and they looked to Canadian manufacturers to fill the gap. The Cartridge Company in Hamilton, which was owned by Frank Wilton Baillie was one of the highest quality low cost producers of shells. Baillie operated an extremely efficient manufacturing operation, and in 1916 returned $758,000 in "excess profits" to the British Crown.

In 1917, when Britain needed trained aviators, they came to Canada to set up training operations in Ontario (15 squadrons) and Texas (15 squadrons). But they also needed training aircraft. The Imperial Munitions Board looked to Frank Wilton Baillie to setup and manufacture JN-4 Canucks, Avro 504's, and the US Navy selected this company to manufacture Felixstowe F.5 flying boats. On December 15, 1916 Canadian Aeroplanes Limited was born.

First Military Aeroplane Built in Canada — JN-4 Canuck serial C101

The JN-4 Canuck was independently derived from the Curtiss JN-3, as was the American built Curtiss JN-4. The two were different from the beginning. Frithiof Gustof Ericson was brought over from the buy-out of Curtiss and was the chief designer at Canadian Aeroplanes Limited. Ericson had also been one of the designers of the C-1 Canada Bomber, a large twin engine aircraft that had been passed over by the Royal Flying Corps.

Canadian Aeroplanes Limited went on to build from January 1917 to December 1918 1,260 (many references quote 1,210) JN-4 Canucks plus and additional 1,600 in spare parts equivalents.

Serial C101 from Canadian Aeroplanes Limited, built in January 1917 was the first manufacture of a successful military aeroplane in Canada.

collection.ngenium.ca Archives CAL-P-OFY-040a

collection.ngenium.ca Archives CAL-P-OFY-041b

collection.ngenium.ca Archives CAL-P-OFY-041a

Bert Acosta went on to be a very significant person in early aviation. Sir Frank Wilton Baillie who was obviously an exceptional manufacturing manager died tragically of complications from cancer surgery in 1921.

Avro 504

collection.ngenium.ca Archives CAL-P-OSY-061

collection.ngenium.ca Archives CAL-P-OSY-063

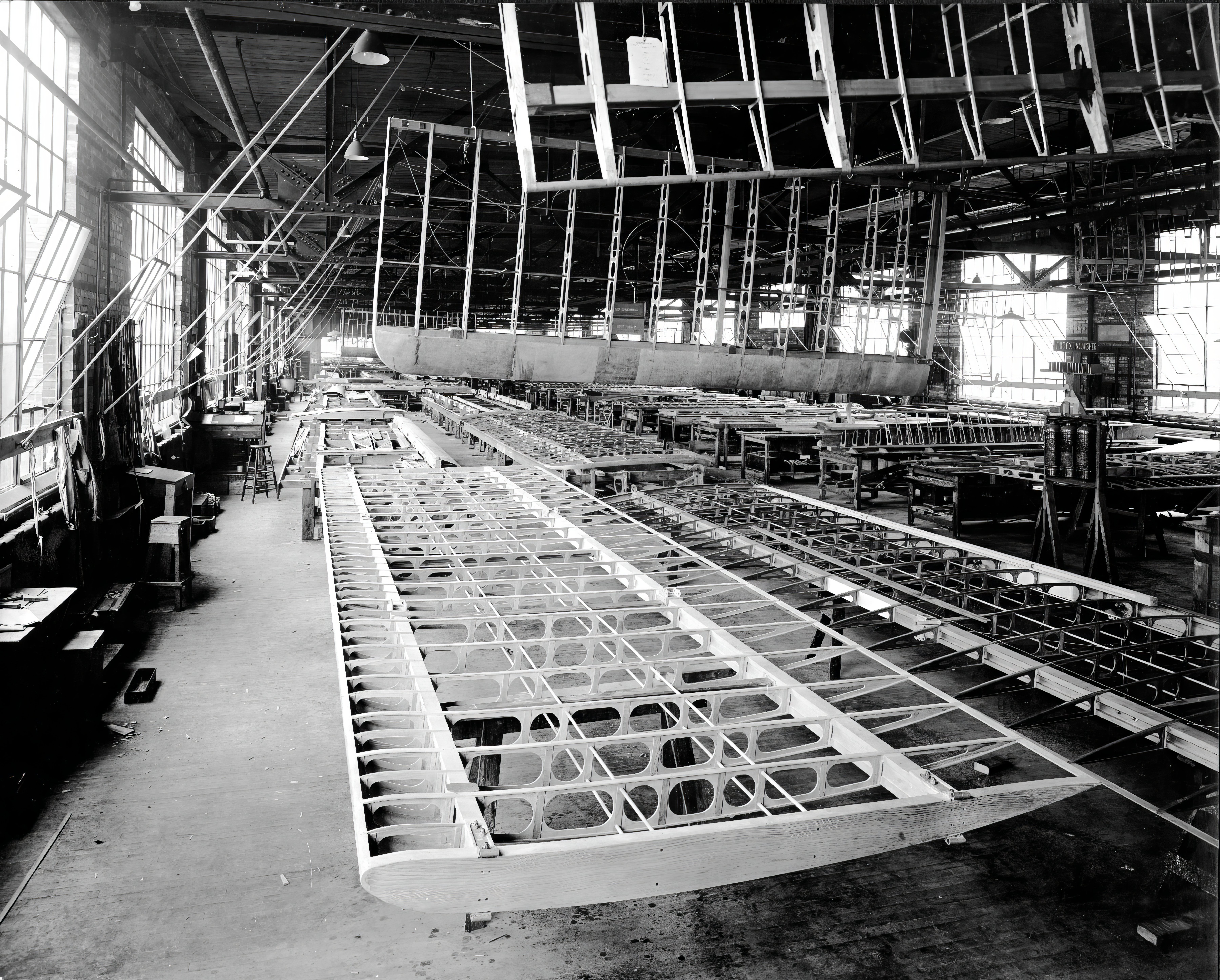

The 504 was the newest training aircraft. Although Canadian Aeroplanes Limited had built 100 of these aircraft, very few were assembled prior to armistice in November 1918.

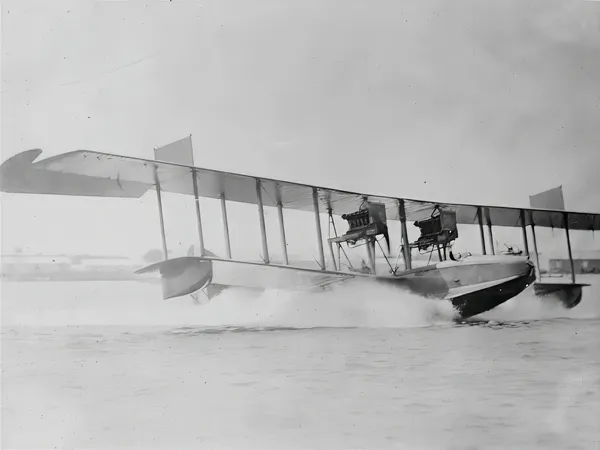

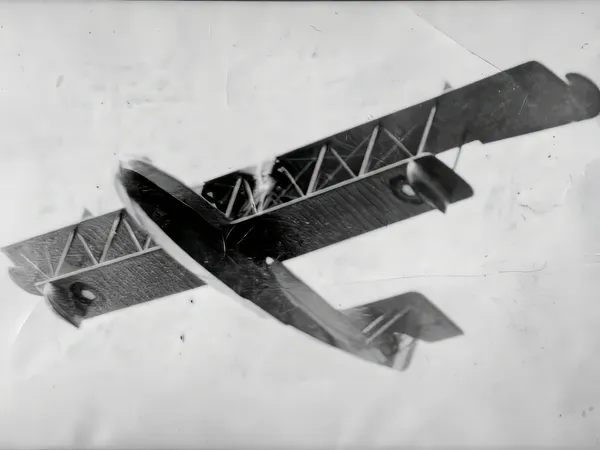

Felixstowe F.5 Flying Boat

collection.ngenium.ca Archives CAL-P-OFFB-031

collection.ngenium.ca Archives CAL-P-OFFB-039

collection.ngenium.ca Archives CAL-P-OFFB-035

The Felixstowe F.5 was a 2 engine flying boat designed in Britain at the Felixstowe Naval air base, by the Royal Navy. Canadian Aeroplanes Limited was contracted to build 30 of these impressive aircraft.

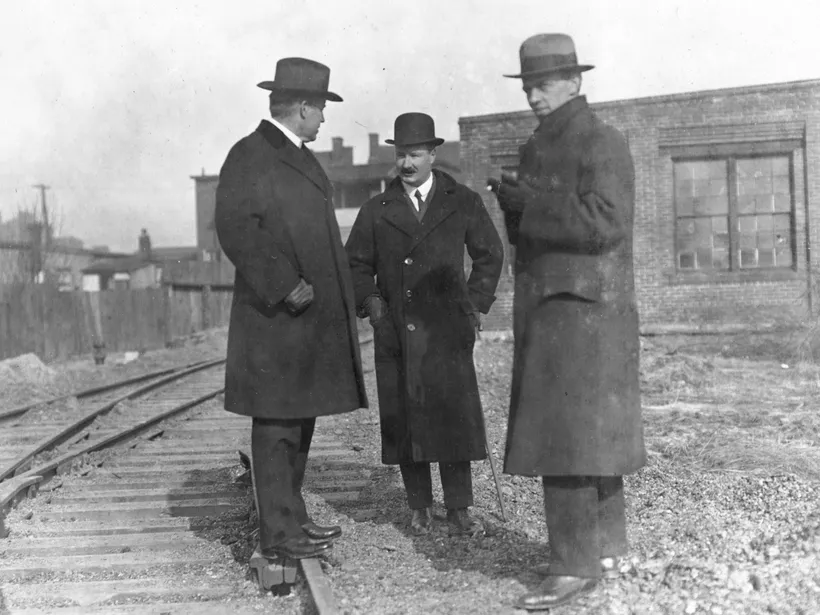

Sir Frank Wilton Baillie

Sir Frank Wilton Baillie was a financier and industrialist who, from 1901 to 1921, had a remarkable career. He died in 1921 from the complications of surgery to remove a cancer.

Sir Frank Wilton Baillie was directly involved in various savings and loan companies and life insurance companies. He was managing director of Dominion Securities, then subsequently general manager of Metropolitan Bank (merged with Bank of Nova Scotia - 1902). Later he was instrumental in forming many investment firms.

As an industrialist, Baillie formed:

- Canadian Cartridge Company (1914 to supply the Great War).

- Canada Steel Company,

- Dominion Steel Castings,

- Canada / Burlington Steel and

- Dominion Steel Foundry (later all became DOFASCO).

The Canadian Cartridge company contracted to produce two million 18-pounder cartridges. The war contracts were so successful that Baillie returned $758,000 to the British crown as "excess profits" ($14.8 million in 2025 dollars).

Baillie was recognized both in Canada (Imperial Munitions Board) and Britain (Ministry of Munitions) as a strong business leader for quality production at a sustainable price. The Imperial Munitions Board facilitated the buying of the small Curtiss factory in Toronto and installed Baillie as president of the new company, Canadian Aeroplanes Limited. Canadian Aeroplanes Limited would produce the JN-4 "Canuck", which was independently derived from the JN-3.

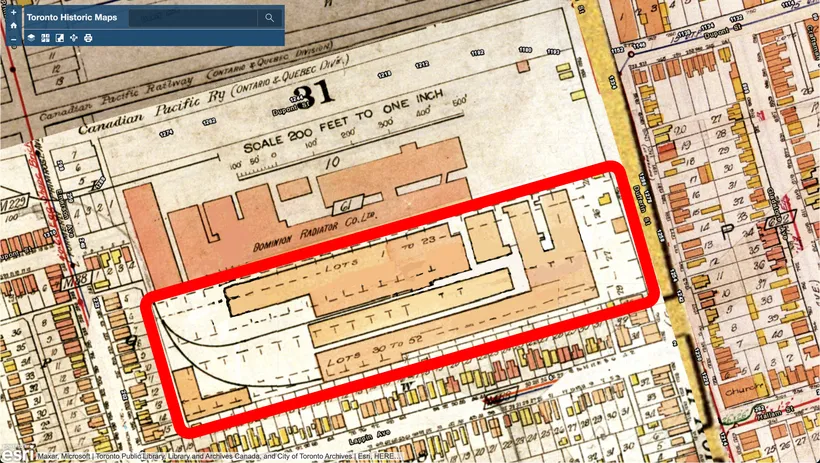

Baillie moved quickly to start manufacturing. The small Curtiss Aeroplanes and Motors Limited factory in Toronto was acquired in December 15, 1916. Additional space was rented and manufacturing of the new JN-4 began immediately. On January 26, 1917 Canadian Aeroplanes Limited signed a contract with Jackson-Lewis Contractors to built a new and much larger factory. To the astonishment of most observers, within ten weeks he had a new, fully equipped factory operating on six acres on Dufferin Street, in Toronto’s west-end industrial district. By November aircraft were leaving at a rate of more than 50 per week. Valued at nearly 14 million dollars, the aircraft produced were primarily Canadian Curtiss JN-4s. (The number of JN-4s is estimated at 1,260 complete planes plus parts equal to about 1,600 more; 100 Avro 504's and 30 Felixstowe F.5 flying boats were also built for the American government in 1918–19.) Baillie’s effort was remarkable.

Materials were sourced locally. For example Irish linen was replaced with Wabasso cotton for covering wings and fuselages and was shipped in from Trois-Rivières and Sitka spruce for frames from British Columbia’s coastal forests. Some 2,400 workers had to be assembled, ranging from skilled woodworkers and machinists to the many women needed to stitch the fabric covered surfaces. Dictionary of Canadian Biography (https://www.biographi.ca/en/bio/baillie_frank_wilton_15E.html)

Sir Frank Wilton Baillie was the first Canadian to receive the Knight Commander of the British Empire, issued by George V in 1918.

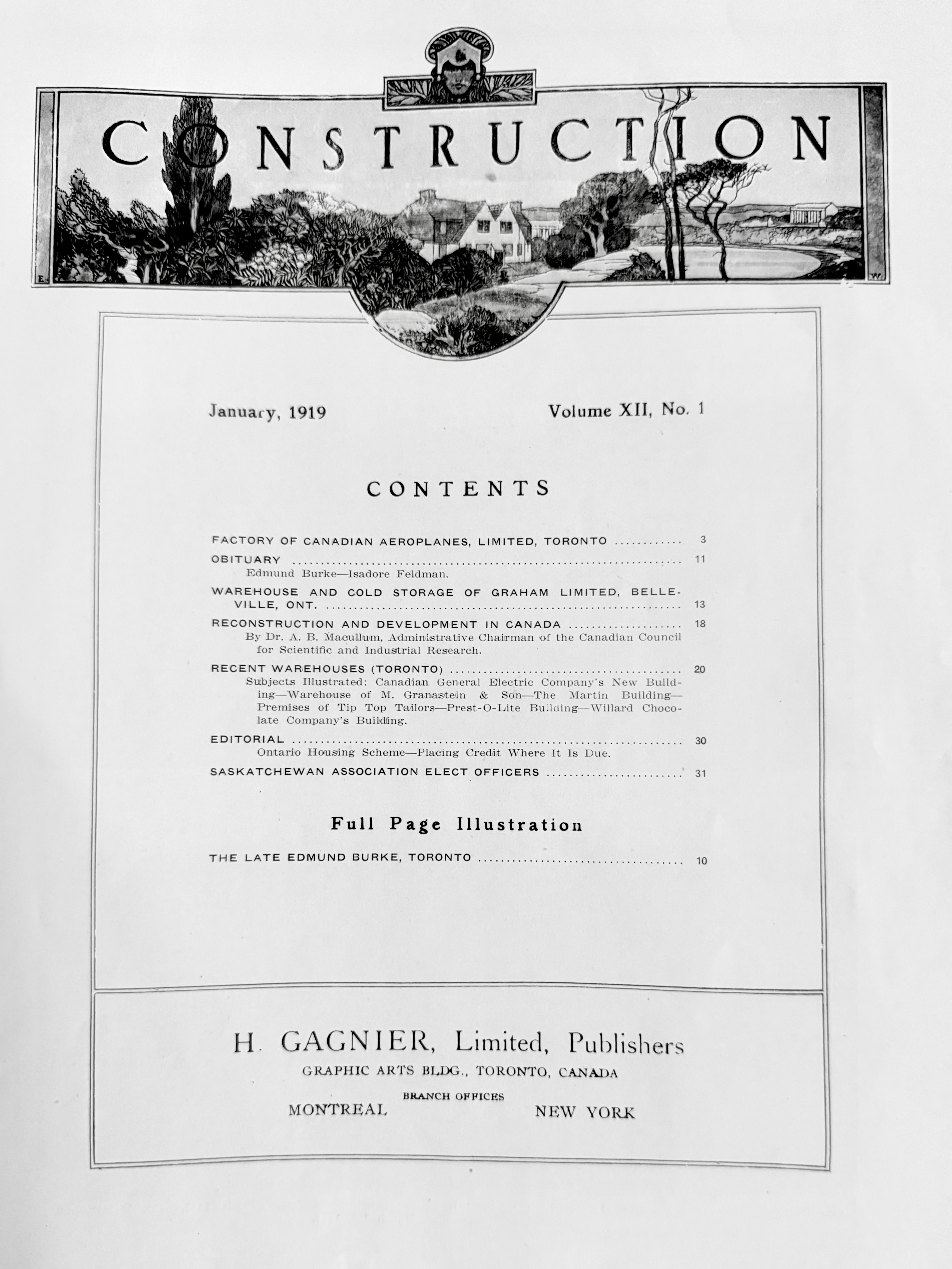

Construction Magazine Excerpts January 1919

Notes to this Reproduction:

- document was obtained from City of Toronto Archives Fonds 1285, File 4, Box 581956 - 4

- only reproduced the portion of the magazine pertaining to Canadian Aeroplanes Limited

- ads shown are highlighting supplying to Canadian Aeroplanes Limited; most ads were omitted.

- All scans were by iPhone

- Images were substituted with equivalents from CASM Archives Ottawa, which are much higher quality. Poorer iPhone scans were only used if higher quality equivalents were not available.

- the annotated highlight boxes were not in the original article

- The factory, at 1260 Dufferin Street in Toronto, originally was 139,000 square feet. 100,000+ square feet were added in increments until mid 1918. The approximately 1/4 million square feet occurs because most buildings are two storey.

- There are multiple building adding up to approximately 240,000 square feet. This factory ran 24 hours per day and employed up to 2,400 people.

PROGRESS VIEWS, FACTORY OF THE CANADIAN AEROPLANES LIMITED

collection.ngenium.ca Archives CAL-P-OFY-004

collection.ngenium.ca Archives CAL-P-OFY-006

collection.ngenium.ca Archives CAL-P-OFY-007

collection.ngenium.ca Archives CAL-P-OFY-010

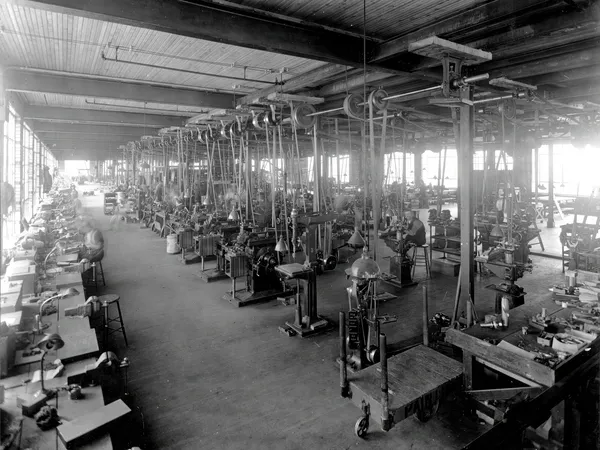

WHEN the British Government decided to train pilots in Canada about two years back, the question was how soon could arrangements be made to produce aeroplanes in this country, as machines could not be imported from England, and the United States had no equipment of this kind to spare.

Mr FW Baillie, now Sir Frank Baillie, was asked to undertake the organization of this work, with results which are now pretty much a matter of history. As an instance of manufacturing enterprise and productive capacity, the factory of the Canadian Aeroplanes, Limited, stands as an important war-time achievement. As a building undertaking, it represents an accomplishment which for speed of construction and organizing ability and resourcefulness has never perhaps been exceeded anywhere.

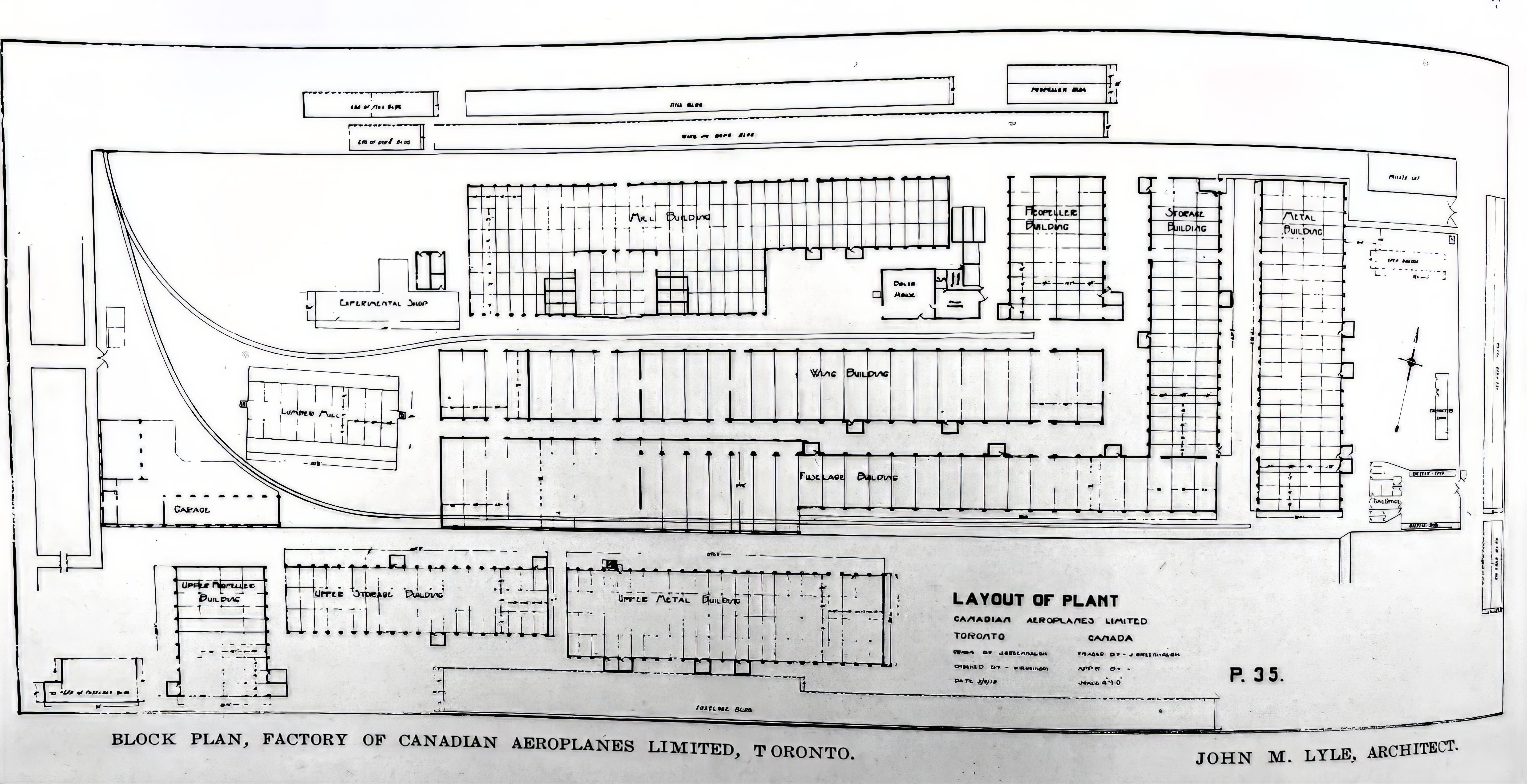

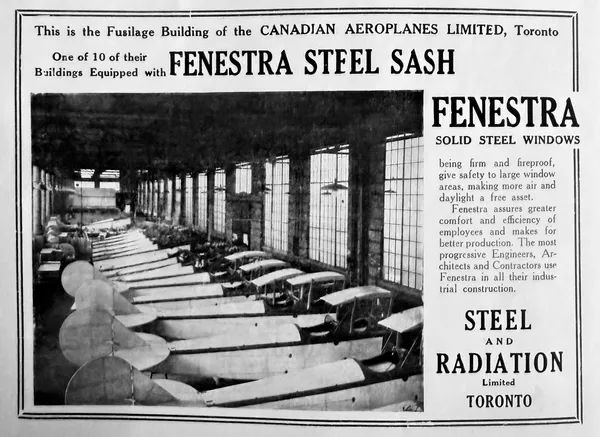

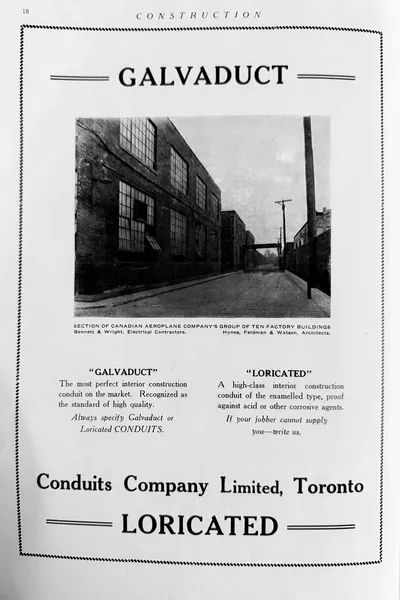

Ten acres of buildings started and completed in sixty-six actual working days is the record established - a feat all the more remarkable when the adverse weather conditions under which the work was carried out is taken into consideration. The group altogether comprises a storage and office building, metal shop, wood- working mill, fuselage building, winged panel building, power house, boiler house, experimental building, wood drying house, garage, and timekeeper's office.

collection.ngenium.ca Archives CAL-P-OFY-015

collection.ngenium.ca Archives CAL-P-OSY-004

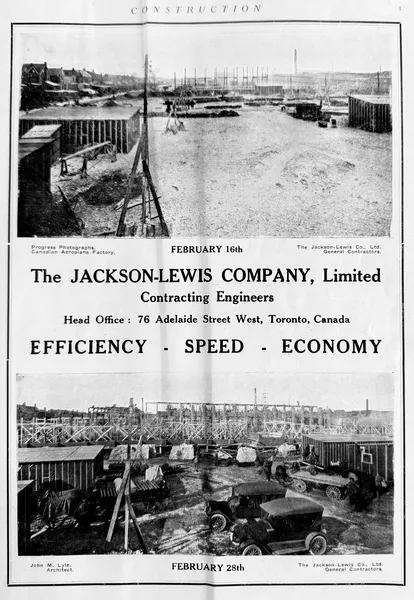

Before the work was started an investigation was made of all possible sites in the vicinity of Toronto suitable for the erection of such a plant. It was necessary to get a level property, if possible, which could be served by railway facilities and be well-placed as regards the labor market. Such a property, comprising approximately ten acres, was found just north of Lappin avenue on Dufferin street. On February 1st, 1917, the same day the property was purchased, teams were put to work breaking up the frozen ground, and construction started on the erection of permanent buildings that would be suitable for general manufacturing® purposes after the war. Immediately on acquiring the site the architect was instructed to begin work on the plans according to requirements previously deter mined at a preliminary meeting held with Sir Frank Baillie and General Manager E T Musson and his staff. The general scheme of the building having been definitely decided on, a local contracting firm was engaged to do the work on a percentage basis. Temporary offices were immediately erected, and trench digging for the first buildings started on the date mentioned.

With the exception of the experimental building, wood-drying building and the timekeeper’s house, the whole group was built of brick on concrete base, with steel column and trusses, metal sash throughout, mill constructed floors and splined plank roofs. Some idea of the rapidity of construction can be gathered from the fact that the company was occupying some of these buildings inside of a month, while within forty-five days' time the manufacture of aeroplane parts was in progress to a considerable extent.

collection.ngenium.ca Archives CAL-P-OFY-005

There was practically no overtime work on the job, and no work on Saturday afternoons, Sundays or at night, save in a few isolated cases, such as some rough labor work and some overtime for painting at the very end. By May 7th, three months and a week after operations started, the buildings were completed, roadways and sidewalks laid, and the contractors’ plant entirely removed from the premises. By deducting Sundays, Saturday afternoons, rainy days and days when it was too cold to work, the total number of full working days amounted to sixty-six.

It is doubtful if such a record has been equalled by any similar war work on this continent. This result was obtained through the hearty co-operation of the owners, architects and contractors, and denotes organizing methods and capabilities quite unsurpassed.

Before any contracts were let, an investigation was made by a Canadian inspection company as to the steel in hand at the time in Montreal, Winnipeg, Hamilton and Toronto, and the contract finally awarded to a local steel firm on the basis of a penalty and bonus system; the contractors to receive a bonus of $100 per day on each building for every day under his schedule for delivery, and to be penalized an equal amount for every day behind such a schedule. Some idea of the speed in delivery and erection of the steel may be gathered from the fact that on a schedule of delivery set for six weeks, the contractors were able to earn a bonus of six thousand dollars.

collection.ngenium.ca Archives CAL-P-OFY-022

collection.ngenium.ca Archives CAL-P-OFY-037

[this image has been substituted for an original image that is no longer available]

collection.ngenium.ca Archives CAL-P-OFFB-015

collection.ngenium.ca Archives CAL-P-OSY-012

collection.ngenium.ca Archives CAL-P-OFFB-025

collection.ngenium.ca Archives CAL-P-OFY-023

collection.ngenium.ca Archives CAL-P-OFY-027

When it is borne in mind that, besides steel columns, beams, etc., there was a great deal of truss work-certain spans being 67½ ft. wide, and other 60 and 45 ft. wide-some idea maybe gathered of the fabrication entailed thereby. The wing panel building, which has a span of 60 ft., is 400 ft long, while the fuselage building, which has a span of 45 ft in one section and 67½ ft. in another, is over 500 ft. long. In order to preclude the possibility of any delay of materials, orders were only given with the strict understanding that deliveries would be promptly made. A contract was made with a local brick company that they were to agree to take no other orders and to supply a continuous haulage of at least twenty teams per day. If, in addition, it was deemed necessary by the architect, they were to ship by rail . At one time bricks were being laid hot from the kilns.

During the first two weeks very severe weather prevailed, the thermometer dropping to 15 to 18 degrees below zero. Special precautions were taken to protect the trenches from the frost, and also the concrete during erection. Later in the spring, owing to the rather wet character of the soil and the fact that snow and ice had accumulated inside the buildings, it was necessary to thaw out same with auxiliary salamanders. A sea of mud was the natural result, and i t was necessary to drain off the water from this mud and fill in with cinders. Steam rollers were put in to crush down this cinder-fill, and it was an interesting sight to see at one end of the building a sea of mud, in the middle a steam roller at work, and at the farther end a gang of men laying the work floors.

The buildings are heated by steam from a central plant, radiators being used instead of piping. This service work was put through in record time by a local heating firm, employed under the general contractors. Owing to the character of the work to be carried on in the plant, it was necessary to have specially well lighted shops, and this has been obtained by the use of large areas of metal sash.

collection.ngenium.ca Archives CAL-P-OFY-035

Special care was also given to the matter of routing materials in the process of manufacture so as to successfully co-ordinate all branches of the work. With this in view, the buildings were planned with a central stock room, distributing the raw material stock on one side to the metal-working plant, and receiving it back again at the other end of this stock building, where it was joined with the finished mill-wood part received at the other side of the stock room, and distributed to the assembling departments. Material from the lumber yards, situated at the west end of the property, likewise progresses in one direction to the stock room. The final assembly, starting from the stock room end of the buildings, progresses toward the shipping department, down the two long buildings.

The following additions were made to the plant during the past year: Second storey on metal building; six dry kilns; nine bay extension to wing and dope building, 180 x 60 ft.; nine bay extension to fuselage building, 180 x 80 ft., and a seven bay extension to fuselage building, 120 x 14 ft. All details of construction are what might be termed standard; that is, all steel is of standard size and lengths. All partitions, etc., throughout the plants are in small units and standardized, so as to permit them being moved from place to place and put up again without cutting.

Selected Advertising from January 1919 Construction Magazine

Canadian Civil Aviation Begins

Although it seems so minor today, the first airmail in Canada (Montreal to Leaside Aerodrome in Toronto) and the first crossing of airmail in the Rockies (Richmond British Columbia to Calgary Alberta) were momentous occasions.

After the First World War there were literally thousands of Curtiss JN-4's and JN-4 Canucks available at very low prices. There were also thousands of airmen who had been trained and had a taste for flying.

collection.ngenium.ca Archives KM-04584

First Airmail - Montreal to Toronto

Canada's first airmail flight was on June 24 1918. Captain Brian Peck of the Royal Air Force and mechanic Corporal CW Mathers took off from the Bois Franc Polo Grounds in Montreal in a JN-4 Curtiss (serial C203) two-seater airplane. They had with them the first bag of mail to be delivered by air in Canada. Wind and rain buffeted the small plane and forced it to make refuelling stops at Kingston (had to fuel with automotive gas, so had to stop in Deseronto for proper fuel) and Deseronto. Finally, at 4:55 p.m., Peck and Mathers landed at the Leaside Aerodrome (now part of Toronto). The first 120 pieces of air mail were delivered in Canada!

But, there is always more to the story. Peck and Mathers initially did not go to Montreal to deliver mail back to Toronto - that was an afterthought. Peck and Mathers flew from Leaside to Montreal on June 20, 1918. They had two purposes: flying aerobatics over Montreal to drum up business for the RAF, and bring back whisky for a wedding. But the weather was poor until the 24th and aerobatics was cancelled. Ontario had been a "dry" province since the Ontario Temperance Act of 1916, and a friend of Peck's needed whisky for an upcoming wedding.

Even on the 24th the weather was barely good enough for the return flight. Montreal members of the Aerial League of the British Empire convinced them to carry 120 pieces of mail back to Toronto in order to create publicity about aviation.

The extra fuel stop in Kingston?

- poor weather, headwinds and rain

- extra weight from the cases of "Old Mull" Scotch whisky resulted in low flying, maximum 40 feet, reducing the normal options that aeroplanes enjoy

The whisky payload was kept secret until 1954 revealed in the 1954 book Canada’s Flying Heritage by Frank Ellis

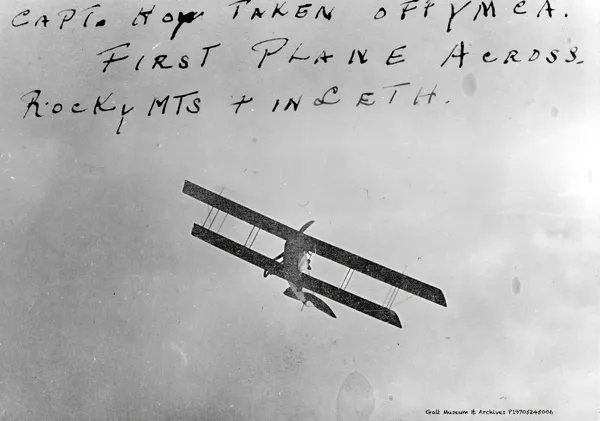

Galt Museum Lethbridge Alberta P19705245006

First Rockies Crossing Airmail - Vancouver to Calgary

The first flight across the Canadian Rockies was on August 7, 1919, by Captain Ernest Charles Hoy in a Curtiss JN-4 biplane (serial C222). He departed from Minoru Park in Richmond British Columbia, flying a route through British Columbia and Alberta, making several stops while demonstrate the viability of airmail service across the mountain range.

Hoy's airmail route was Vancouver - Vernon - Grand Forks - Cranbrook - Lethbridge - Calgary. The entire trip took 16 hours and 42 minutes.

![]() Hoy's account of his flight across the Rockies

Hoy's account of his flight across the Rockies

References

Books on Imperial Munitions and Aviation in Canada during the First World War

![]() The History of Munitions Supply in Canada, 1914-1918, David Carnegie, 1925

The History of Munitions Supply in Canada, 1914-1918, David Carnegie, 1925

![]() Aviation in Canada 1917-18, Lieutenant Alan Sullivan, RAF, 1919

Aviation in Canada 1917-18, Lieutenant Alan Sullivan, RAF, 1919

Dancing in the Sky by CW Hunt

Interviews with Frank Wilton Baillie, grandson of Sir Frank Wilton Baillie

From Wing Commander Fred Hitchins' Collection, University of Western Ontario. These documents were sourced from the Air History Board, a division of the Royal Air Force when Hitchins was posted as an RCAF historian in Britain during the Second World War.

![]() Canadian Aviation Corps 1914-1915

Canadian Aviation Corps 1914-1915

![]() Assessment of Aircraft Construction in Canada by RFC in 1916

Assessment of Aircraft Construction in Canada by RFC in 1916

![]() Canadian Aeroplanes Limited 1917-1919

Canadian Aeroplanes Limited 1917-1919

![]() Report by John S Emery in RFC Canada on progress to date Sepetember / October 1917

Report by John S Emery in RFC Canada on progress to date Sepetember / October 1917

![]() Report by John S Emery in RFC Canada on progress to date Sepetember / October 1917 (transcribed)

Report by John S Emery in RFC Canada on progress to date Sepetember / October 1917 (transcribed)

From City of Toronto Archives

![]() Excerpts from Construction Magazine January 1919

Excerpts from Construction Magazine January 1919

Internet References

![]() Library and Archives Canada - Canadian Aeroplanes Limited

Library and Archives Canada - Canadian Aeroplanes Limited

![]() RCAF Journal Spring 2017, authors: T Higgins, B March, H Halliday, LL Smart, PW Lackenbauer

RCAF Journal Spring 2017, authors: T Higgins, B March, H Halliday, LL Smart, PW Lackenbauer

![]() Dictionary of Canadian Biography, Sir Joseph Wesley Flavelle

Dictionary of Canadian Biography, Sir Joseph Wesley Flavelle

![]() Commodore Frithiof Gustaf Ericson

Commodore Frithiof Gustaf Ericson

![]() Business Profits War Tax Act, 1916

Business Profits War Tax Act, 1916

![]() Imperial Royal Flying Corps (RFC Canada)

Imperial Royal Flying Corps (RFC Canada)

![]() Into the Blue: Pilot Training in Canada, 1917-18 Authors: Hugh A Halliday and Dr Laura Brandon

Into the Blue: Pilot Training in Canada, 1917-18 Authors: Hugh A Halliday and Dr Laura Brandon

![]() ingenium.ca - Canada's First Email JN-4 Canuck

ingenium.ca - Canada's First Email JN-4 Canuck

![]() lethbridgehistory.org - Canada's first aeroplane crossing of the Rocky Mountains, JN-4 Canuck

lethbridgehistory.org - Canada's first aeroplane crossing of the Rocky Mountains, JN-4 Canuck